Service:

Cylinder And Tonner Maintenance

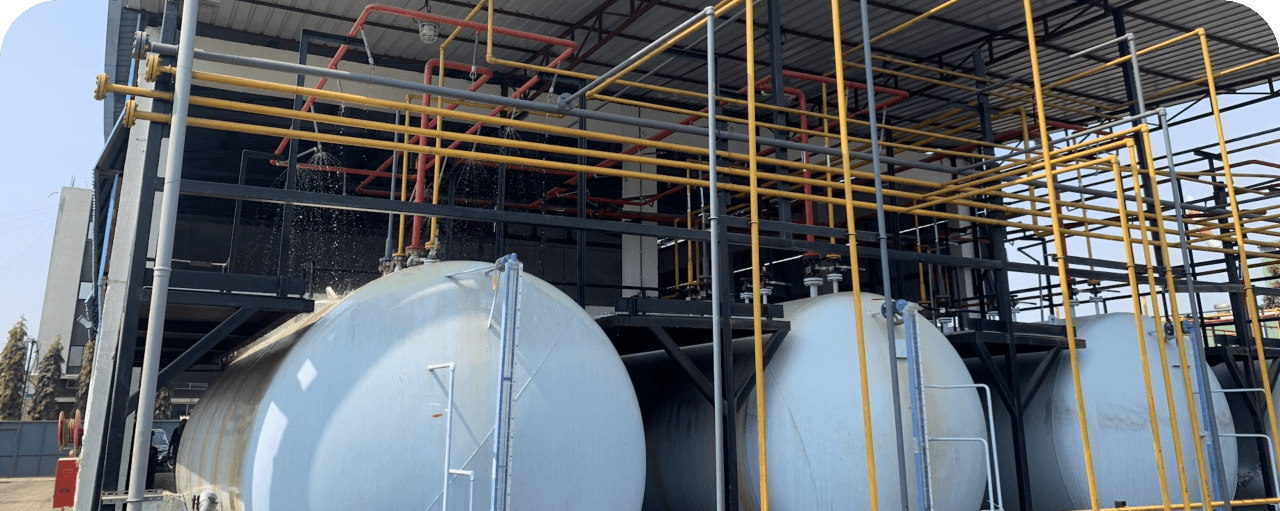

Cylinders and tonners play a critical role in the chemical industry, especially for transporting gases like ammonia. Their reliability and safety directly impact operations, making regular maintenance a must to ensure they stay in top condition. At Jaysons Chemical Industries, our cylinder & tonner maintenance service offers thorough inspections, repairs, and testing to keep your equipment in optimal condition. We’re dedicated to extending the lifespan of your cylinders and tonners, ensuring safety, and helping you stay fully compliant with all industry regulations.

Why You Should Rely on Us for Cylinder & Tonner Maintenance?

Jaysons Chemical Industries is a renowned global supplier and caters to diverse industries worldwide, delivering high-quality solutions for all ammonia related operations. Trust us as your reliable partner for superior and sustainable products.

Customized Maintenance Schedules

Tailored maintenance plans to suit your specific needs and ensure optimal performance.

Advanced Diagnostics

Robust leak prevention

Innovative techniques to prevent leaks, ensuring safe operation.

Quick response & minimal downtime

Fast service to reduce downtime and keep operations running smoothly.

Dedicated customer support

24/7 support for any maintenance-related queries or emergencies.

Certified technicians

Seamless integration

Quality replacement parts

Only high-quality, OEM-standard parts used for repairs or replacements.

Comprehensive documentation

Cost-Effective preventative maintenance

Proactive maintenance to prevent costly repairs and ensure long-term reliability.

Eco-friendly practices

Environmentally responsible methods for cleaning, testing, and maintaining cylinders.

Extended warranty on services

Enjoy peace of mind with extended warranties on our maintenance services.

Why Choose JCI?

Safe, timely, sustainable, and industry-focused

transport solutions.

Safety First

Certified vehicles and trained drivers prioritize material and environmental safety.

Timely Delivery

On-time deliveries with real-time GPS tracking for full visibility.

Sustainable Choice

BS6 and BS4-compliant vehicles for an eco-friendly approach.

Diverse Customer Base

Our Liquor Ammonia Manufacturing & Bottling Plant Services Include:

1. Routine Inspections and Safety Checks

- Say goodbye to corrosion! Preventing wear and tear of cylinders and tonners.

- Valves and regulators check: Ensuring that valves and regulators are functioning properly and securely attached is crucial for the safe operation of gas storage units.

- Seal and gasket inspection: Inspecting of seals and gaskets to ensure they are intact and providing an effective seal to prevent leaks.

- Frequency: Depending on the type of use and regulatory requirements, these inspections can be performed on a regular basis—either monthly, quarterly, or annually.

2. Cleaning and Decontamination

3. Pressure Testing

4. Valve and Regulator Maintenance

- Valve Inspection and Replacement: We inspect valves for damage, corrosion, or malfunction. If necessary, we replace or repair faulty valves to prevent leaks and operational issues.

- Regulator Calibration: Ensuring that pressure regulators are accurately calibrated is essential for maintaining consistent and safe gas flow.

By maintaining these critical components, we ensure that the cylinders and tonners are safe to use and operate efficiently.

5. Painting

“With our specialized maintenance services, you can be confident that your cylinders and tonners will operate safely, reliably, and in full compliance with industry regulations. Trust Jaysons Chemical Industries to maintain your equipment’s integrity and longevity.”

Our services

Transportation of ammonia

Cylinder and tonner maintenance

PESO approvals for ammonia

Plant setup

DeNOx (SCR/SNCR) Projects

Degassing of IMO tanks, tonners, cylinders

Our testimonials

Fatima Bichu

Aarti Industries

We have enriching years of association with Jaysons Chemical Industries and their best attribute is transparency in doing business. Their prompt response regarding the availability as well as supplies of materials has always helped us in taking quick decisions. Thanks to their impeccable service, Jaysons Chemical Industries is the first name that comes to our mind when we think about RM supplies.

Hitesh Koul

Avantor Performance Materials, Inc.

We cherish the transparent association which we are having with Jaysons Chemical Industries (JCI) from decades. The seamless approach from JCI has really helped us scale our opportunities and association. Close your eyes as you can 100% bank upon them.

Archana Gorde

Prasol Chemicals

We buy Liquor Ammonia 25% from Jaysons Chemical Industries. I must say they are very good vendor in terms of quality, price, service. They are genuine and are customer centric.

Get in Touch for Ammonia Transportation in India

tailored to your needs.