Service:

Plant Setup

Why partner with us for Liquor ammonia manufacturing & bottling?

Our Liquor Ammonia Manufacturing & Bottling Plant services offer Expert Project Management, ensuring smooth processes from design to commissioning. We provide End-to-End Solutions, covering everything from regulatory approvals to mechanical and civil installation and future scalability. With a strong emphasis on Safety and Compliance, we meet the highest industry standards to ensure safe, efficient plant operation. We offer Customized Solutions tailored to your unique production needs and long-term goals. Our plants are designed for Sustainability and Efficiency, optimizing energy use and resources while prioritizing environmentally friendly practices.

Comprehensive plant design & installation

Full-spectrum services from design to installation, optimized for productivity and efficiency.

Cutting-edge engineering

Industry-specific expertise

International standards compliance

Sustainability-driven design

Turnkey solutions

Complete, end-to-end project management, from concept to commissioning.

Advanced automation & monitoring

Scalability for future growth

Easily scalable plants that grow with your business needs.

Proven track record of successful projects

Dedicated post-installation Support

Cost-effective solutions

Efficient, cost-effective ammonia plants that maximize ROI without compromising on quality.

Tailored to meet your specific needs

Why Choose JCI?

Safe, timely, sustainable, and industry-focused

transport solutions.

Safety First

Certified vehicles and trained drivers prioritize material and environmental safety.

Timely Delivery

On-time deliveries with real-time GPS tracking for full visibility.

Sustainable Choice

BS6 and BS4-compliant vehicles for an eco-friendly approach.

Diverse Customer Base

Our Liquor Ammonia Manufacturing & Bottling Plant Services Include:

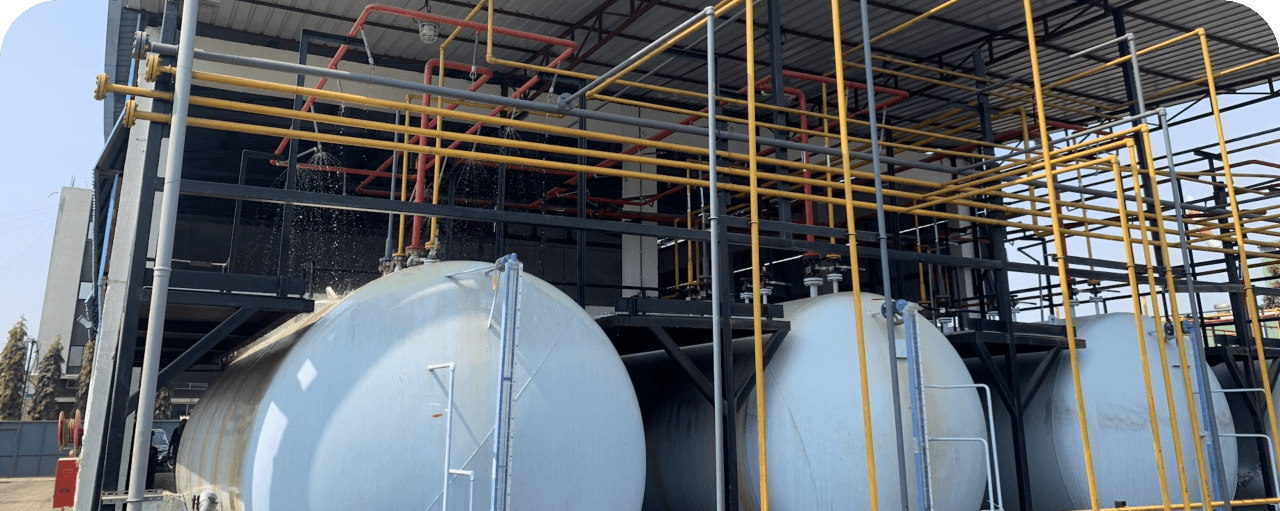

1. Setting Up a Liquor Ammonia Manufacturing Plant

2. Design and oversight of fabrication of Tanks in Facilities

We specialize in the design of storage tanks tailored for liquor ammonia manufacturing. This includes anhydrous ammonia storage tanks, process tanks, storage tanks and scrubber tanks. Using the right materials and the right sizes to comply with PESO while also utilizing the space effectively. Custom fabrication of tanks are designed to withstand the high pressures and chemical properties of ammonia. Quality Control & rigorous testing and inspection of each tank is done to ensure that it meets standards for safety and durability.

3. Erecting Process Tanks and Storage Vessels

Our expertise extends to the erection of process tanks and storage vessels used for storing ammonia and ammonia solution. Whether it’s for short-term storage or large-scale bulk storage, we look after the safety and efficient installation of ammonia storage vessels, ensuring stability and operational integrity. We incorporate industry-standard safety features such as pressure relief valves, leak detection systems, and emergency venting mechanisms.

4. Setting Up an Ammonia Gas Bottling Plant

Our ammonia gas bottling plant setup services involve a range of solutions to ensure safe and efficient ammonia storage, filling, and distribution. We ensure that the bottling plant adheres to all safety, regulatory, and environmental standards. We integrate automated systems for the filling, capping, and sealing of ammonia cylinders, improving efficiency and reducing human error.

5. Collaborating with Clients for Future Requirements and Space Allocation

We work closely with our clients to understand both current and future requirements for plant operations. Our expert team helps with advanced space allocation to facilitate future expansion, ensuring that your plant is scalable as your business grows.

“Choose us for a plant that performs, scales, and lasts. Built to global standards, tailored to your goals — let’s power your vision, sustainably.”

Our services

Transportation of ammonia

Cylinder and tonner maintenance

PESO approvals for ammonia

Plant setup

DeNOx (SCR/SNCR) Projects

Degassing of IMO tanks, tonners, cylinders

Our testimonials

Fatima Bichu

Aarti Industries

We have enriching years of association with Jaysons Chemical Industries and their best attribute is transparency in doing business. Their prompt response regarding the availability as well as supplies of materials has always helped us in taking quick decisions. Thanks to their impeccable service, Jaysons Chemical Industries is the first name that comes to our mind when we think about RM supplies.

Hitesh Koul

Avantor Performance Materials, Inc.

We cherish the transparent association which we are having with Jaysons Chemical Industries (JCI) from decades. The seamless approach from JCI has really helped us scale our opportunities and association. Close your eyes as you can 100% bank upon them.

Archana Gorde

Prasol Chemicals

We buy Liquor Ammonia 25% from Jaysons Chemical Industries. I must say they are very good vendor in terms of quality, price, service. They are genuine and are customer centric.

Get in Touch for Ammonia Transportation in India

tailored to your needs.